Overview

SRBE-10 Mastic Emulsion Plant is specially designed based on our years of experience in mastic and bitumen emulsion production and various demands from clients. It is simple in structure and easy to operate, and it can be used in all kinds of production of mastic emulsion. The capacity is a maximum of 8t/h.

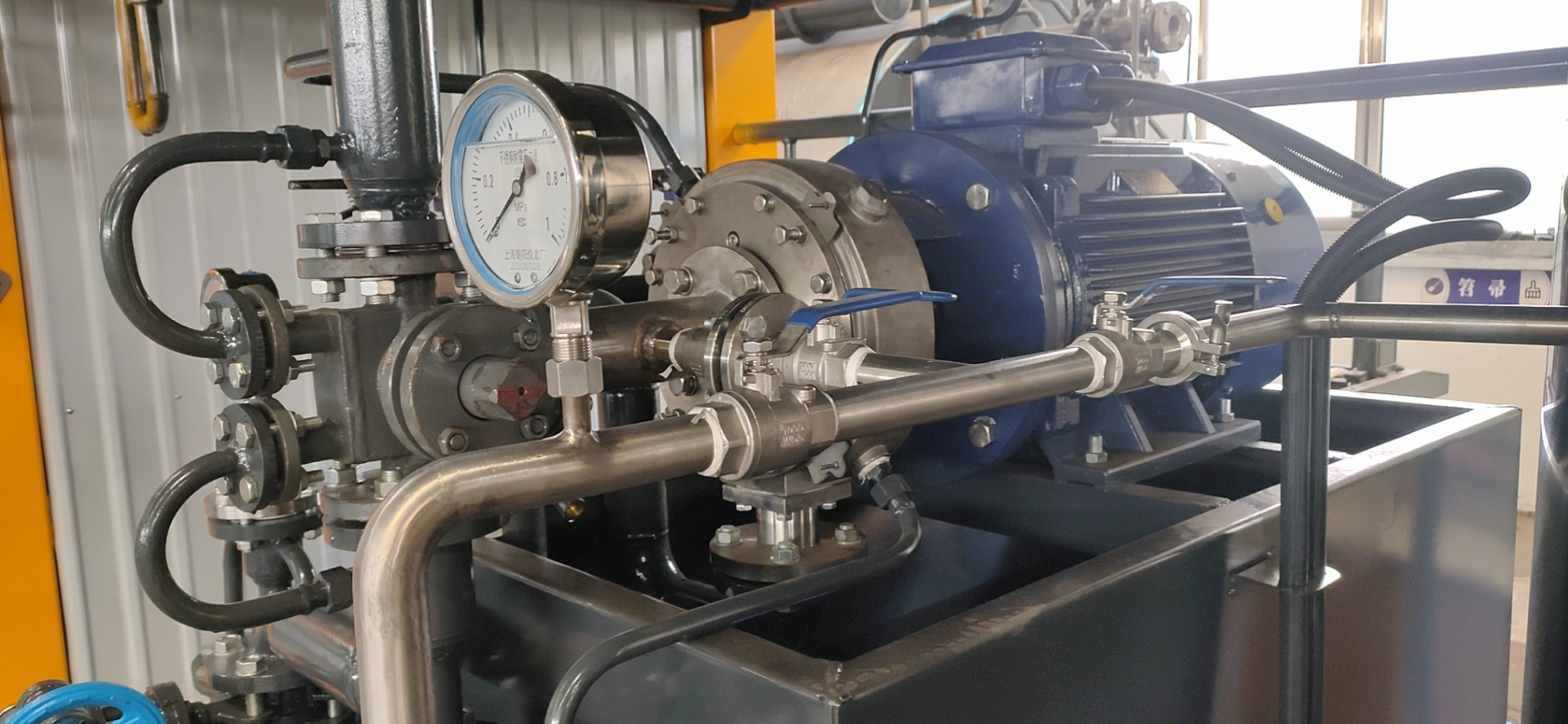

The plant is consisting of two 3.5m³ soap water tanks equipped with a powerful mixer that can mix all different types of filler to soap phase, a bitumen unit, hot water unit, a well-designed colloid mill which can make fine particle size, cooling unit, control cabin, filter, valves, flowmeters, and pipelines, which has a full configuration with compact structure.

01

Mastic Emulsion bitumen types

10%-60% emulsion bitumen

30-60% modified emulsion bitumen

30%-50% Emulsified SBS Modified bitumen

02

Charactristics

Capacity : 8 t/h

Heating system: Thermal oil

Emulsion Fineness: More than 90% smaller than 5μm

03

Advantages

• Container type, easy to move, installs, and operates.

• Automatic control and raw material dispending system

• The ratio accurately, with visual operation

• Corrosion resistant design, milling machine, tank and pipelines is made by stainless steel or PPR.